Robotic Assembly from CAD

ABOUT THE PROJECT

At a glance

A recent developing trend in automatic manufacturing is a move toward small production volumes and high product variability. In such a rapid production pipeline, the tedious manual engineering of robot controllers can be a bottleneck, motivating the use of AI for expediting the process. In particular, in this work we focus on the task of robotic assembly. Robotic assembly is particularly challenging as it involves object manipulation with contacts, and handling friction is often a substantial part of completing the task. For example, think of attaching a nut onto a bolt. Contacts, and friction, however, are notoriously hard to model computationally, making classical control approaches difficult.

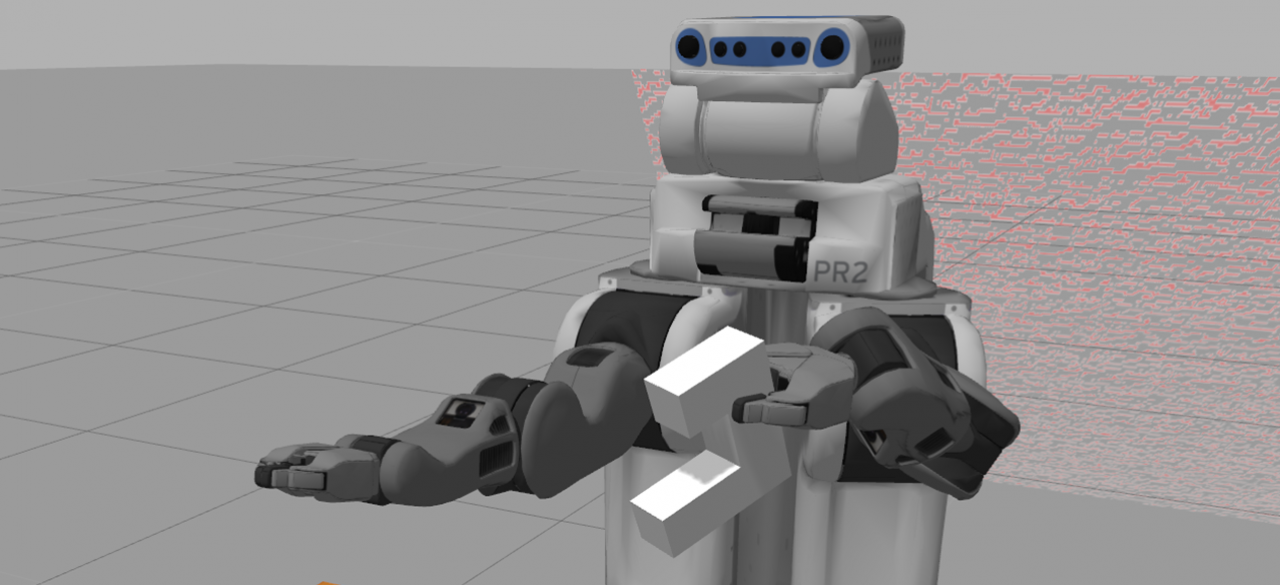

Our goal is to develop methods for exploiting prior information in the form of object Computer aided design (CAD) models in Reinforcement Learning (RL) algorithms, and investigate their application to robotic assembly tasks using the PR2 robot. We will focus on model-based RL algorithms from the guided policy search (GPS) family, which have been demonstrated to efficiently learn torque control in contact-rich manipulation tasks. We are developing methods for exploiting prior information in the form of object CAD models in RL algorithms, and investigate their application to robotic assembly tasks using the PR2 robot. We will focus on model-based RL algorithms from the guided policy search (GPS) family, which have been demonstrated to efficiently learn torque control in contact-rich manipulation tasks.

Our goal is to develop methods for exploiting prior information in the form of object Computer aided design (CAD) models in Reinforcement Learning (RL) algorithms, and investigate their application to robotic assembly tasks using the PR2 robot. We will focus on model-based RL algorithms from the guided policy search (GPS) family, which have been demonstrated to efficiently learn torque control in contact-rich manipulation tasks. We are developing methods for exploiting prior information in the form of object CAD models in RL algorithms, and investigate their application to robotic assembly tasks using the PR2 robot. We will focus on model-based RL algorithms from the guided policy search (GPS) family, which have been demonstrated to efficiently learn torque control in contact-rich manipulation tasks.

| Principal investigators | researchers | themes |

|---|---|---|

| Pieter Abbeel | Aviv Tamir |